All Categories

View All >-

Angle of Chamfer r1smin TIMKEN 500RX2345A Four-Row Cylindrical Roller Radial BearingsSee More>

Angle of Chamfer r1smin TIMKEN 500RX2345A Four-Row Cylindrical Roller Radial BearingsSee More> -

Width B TIMKEN 390RY2103 Cylindrical Roller Radial BearingSee More>

Width B TIMKEN 390RY2103 Cylindrical Roller Radial BearingSee More> -

150 mm x 320 mm x 65 mm Dynamic load, C NTN NU330C4 Single row Cylindrical roller bearingSee More>

150 mm x 320 mm x 65 mm Dynamic load, C NTN NU330C4 Single row Cylindrical roller bearingSee More> -

Bearing ring (inner ring) WS mass NTN WS81216 Thrust cylindrical roller bearingsSee More>

Bearing ring (inner ring) WS mass NTN WS81216 Thrust cylindrical roller bearingsSee More>

Featured Products

Our Manufacturer with main products: Four-Row Cylindrical Roller Radial Bearings, Cylindrical Roller Radial Bearing, Single row Cylindrical roller bearing

-

Bearing ring (inner ring) WS mass NTN WS81216 Thrust cylindrical roller bearings

Bearing ring (inner ring) WS mass NTN WS81216 Thrust cylindrical roller bearings

-

Max operating temperature, Tmax NTN GS89314 Thrust cylindrical roller bearings

Max operating temperature, Tmax NTN GS89314 Thrust cylindrical roller bearings

-

Cage assembly reference NTN 81108T2 Thrust cylindrical roller bearings

Cage assembly reference NTN 81108T2 Thrust cylindrical roller bearings

-

D NTN GS81226 Thrust cylindrical roller bearings

D NTN GS81226 Thrust cylindrical roller bearings

-

Bearing ring (outer ring) GS mass NTN GS81215 Thrust cylindrical roller bearings

Bearing ring (outer ring) GS mass NTN GS81215 Thrust cylindrical roller bearings

-

T NTN 81106T2 Thrust cylindrical roller bearings

T NTN 81106T2 Thrust cylindrical roller bearings

-

B NTN GS81216 Thrust cylindrical roller bearings

B NTN GS81216 Thrust cylindrical roller bearings

-

B NTN GS89315 Thrust cylindrical roller bearings

B NTN GS89315 Thrust cylindrical roller bearings

-

B NTN WS89318 Thrust cylindrical roller bearings

B NTN WS89318 Thrust cylindrical roller bearings

-

Brand NTN K81122T2 Thrust cylindrical roller bearings

Brand NTN K81122T2 Thrust cylindrical roller bearings

-

Manufacturer Name NTN WS89317 Thrust cylindrical roller bearings

Manufacturer Name NTN WS89317 Thrust cylindrical roller bearings

-

Product Group - BDI NTN K81115T2 Thrust cylindrical roller bearings

Product Group - BDI NTN K81115T2 Thrust cylindrical roller bearings

-

Manufacturer Name NTN WS81208 Thrust cylindrical roller bearings

Manufacturer Name NTN WS81208 Thrust cylindrical roller bearings

-

Minimum Buy Quantity NTN WS81217 Thrust cylindrical roller bearings

Minimum Buy Quantity NTN WS81217 Thrust cylindrical roller bearings

-

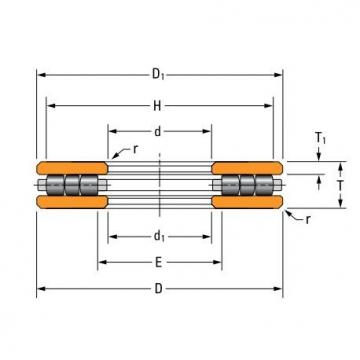

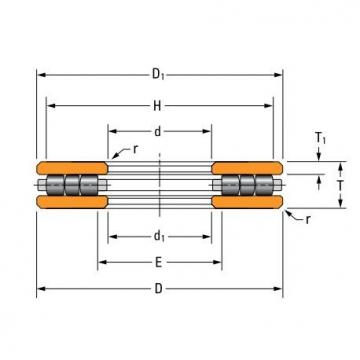

r - Fillet Chamfer TIMKEN 160TP165 Thrust cylindrical roller bearings

r - Fillet Chamfer TIMKEN 160TP165 Thrust cylindrical roller bearings

-

Manufacturer Name NTN WS81218 Thrust cylindrical roller bearings

Manufacturer Name NTN WS81218 Thrust cylindrical roller bearings

-

Nlim (grease) NTN 81209T2 Thrust cylindrical roller bearings

Nlim (grease) NTN 81209T2 Thrust cylindrical roller bearings

-

D1 NTN 81214L1 Thrust cylindrical roller bearings

D1 NTN 81214L1 Thrust cylindrical roller bearings

-

Bearing ring (inner ring) WS mass NTN WS89306 Thrust cylindrical roller bearings

Bearing ring (inner ring) WS mass NTN WS89306 Thrust cylindrical roller bearings

-

Eb NTN K81113T2 Thrust cylindrical roller bearings

Eb NTN K81113T2 Thrust cylindrical roller bearings

-

Cage assembly mass NTN 81215T2 Thrust cylindrical roller bearings

Cage assembly mass NTN 81215T2 Thrust cylindrical roller bearings

-

D NTN GS89311 Thrust cylindrical roller bearings

D NTN GS89311 Thrust cylindrical roller bearings

-

Minimum Buy Quantity NTN WS81212 Thrust cylindrical roller bearings

Minimum Buy Quantity NTN WS81212 Thrust cylindrical roller bearings

-

rs min NTN WS81210 Thrust cylindrical roller bearings

rs min NTN WS81210 Thrust cylindrical roller bearings

-

Brand NTN WS81100 Thrust cylindrical roller bearings

Brand NTN WS81100 Thrust cylindrical roller bearings

-

Brand NTN 81105T2 Thrust cylindrical roller bearings

Brand NTN 81105T2 Thrust cylindrical roller bearings

-

Min operating temperature, Tmin NTN GS81101 Thrust cylindrical roller bearings

Min operating temperature, Tmin NTN GS81101 Thrust cylindrical roller bearings

-

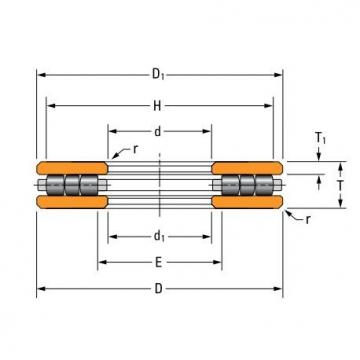

Static Load Rating TIMKEN 220TP174 Thrust cylindrical roller bearings

Static Load Rating TIMKEN 220TP174 Thrust cylindrical roller bearings

-

B NTN WS89312 Thrust cylindrical roller bearings

B NTN WS89312 Thrust cylindrical roller bearings

-

Ca NTN 81208T2 Thrust cylindrical roller bearings

Ca NTN 81208T2 Thrust cylindrical roller bearings

-

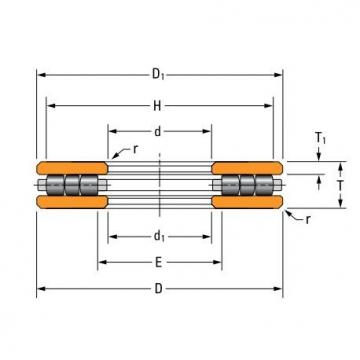

Dynamic Load Rating TIMKEN 220TP176 Thrust cylindrical roller bearings

Dynamic Load Rating TIMKEN 220TP176 Thrust cylindrical roller bearings

-

Product Group - BDI NTN GS81117 Thrust cylindrical roller bearings

Product Group - BDI NTN GS81117 Thrust cylindrical roller bearings

-

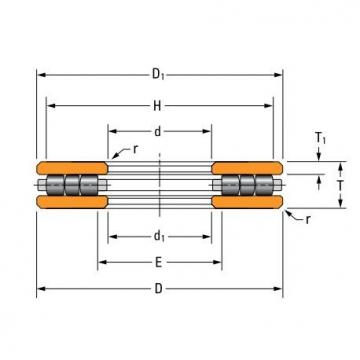

Static Load Rating TIMKEN J-903-A Thrust cylindrical roller bearings

Static Load Rating TIMKEN J-903-A Thrust cylindrical roller bearings

-

Bearing Type TIMKEN E-2311-A Thrust cylindrical roller bearings

Bearing Type TIMKEN E-2311-A Thrust cylindrical roller bearings

-

Eb NTN 81103T2 Thrust cylindrical roller bearings

Eb NTN 81103T2 Thrust cylindrical roller bearings

-

Lw NTN K81105L1 Thrust cylindrical roller bearings

Lw NTN K81105L1 Thrust cylindrical roller bearings

-

Bearing ring (outer ring) GS mass NTN GS81111 Thrust cylindrical roller bearings

Bearing ring (outer ring) GS mass NTN GS81111 Thrust cylindrical roller bearings

-

D1 NTN 81206T2 Thrust cylindrical roller bearings

D1 NTN 81206T2 Thrust cylindrical roller bearings

-

d NTN WS81228 Thrust cylindrical roller bearings

d NTN WS81228 Thrust cylindrical roller bearings

-

Max operating temperature, Tmax NTN GS81220 Thrust cylindrical roller bearings

Max operating temperature, Tmax NTN GS81220 Thrust cylindrical roller bearings

Four-Row Cylindrical Roller Radial Bearings FAQS

QWhat is features of four-row cylindrical roller bearings?

AExceptional high load carrying capacity Because of their high number of rollers, four-row cylindrical roller bearings are suitable for very heavy radial loads. Low friction (Roller end / flange contact area) The open flange design (fig. 1), together with the roller end design and surface finish, promote lubricant film formation resulting in lower friction. Long service life The logarithmic roller profile reduces edge stresses at the roller/raceway contact (fig. 2) and sensitivity to misalignment and shaft deflection. Enhanced operational reliability The surface finish on the contact surfaces of the rollers and raceways supports the formation of a hydrodynamic lubricant film. Separable and interchangeable The separable components of SKF four-row cylindrical roller bearings are interchangeable. This facilitates mounting and dismounting, as well as maintenance inspections. High speed capability The cage designs are suitable for high speeds, rapid accelerations and peak loads. Low cross-sectional height The low cross-sectional height of four-row cylindrical roller bearings allows for relatively large roll neck diameters compared to the roll diameter.

QWhat is Cylindrical Roller Radial Bearing?

ACylindrical Roller Bearings are designed to carry heavy radial loads. These bearings are made with a single row, two rows, or multi-rows of rolling elements to meet an application's radial load requirement. Available in many standard series and configurations, they are widely used in multiple industries. The combination of high load capacity, moderate speed rating, and industry interchangeability make it one of the most popular bearing designs. These are produced in ISO series metric, ABMA series metric and inch, journal type, Full Complement series, multi-row series, and cluster mill sizes. These bearings are dimensionally interchangeable to same numbered and sized bearings in the industry. Components of journal bearings and other standard series are made interchangeable with other manufacturer's components. Many mounting arrangements can be achieved with the multiple configurations available with same load capacity for a given I.D., O.D. and width.

QWhat is Single row Cylindrical roller bearing?

ASingle row Cylindrical Roller Bearings are designed to support heavy radial loads and are some of the most common bearings used around the world. These roller bearings consist of an Outer Race, Bronze or Steel Cage, a complement of rollers, and usually an Inner Race. They are available in ISO and ABMA series. The ISO series is metric dimensioned, with a brass cage. Bearings designated with the “E” suffix are Extra Capacity. They are re-designs of original geometry that increase radial load capacity. These bearings are designed to be dimensionally interchangeable with the same basic size of other manufacturers and are supplied with C3 internal radial clearance unless specified. The ABMA series are metric or inch dimensioned and interchangeable with other manufacturers as well. They are supplied with a machined brass cage or an alternate cage of machined steel (SM) or stamped steel (SS) when needed. The standard internal radial clearance provided is designed to allow interference fit of inner race while keeping the bearing free mounted. The large assortment of Inner and Outer Race configurations lend to their widespread use in electric motors, gearboxes, and general industry applications.

QWhat is Roller thrust bearings?

ARoller thrust bearings carry pure thrust, or axial, loads with little or no radial forces. They use barrel-shaped rolling elements to carry single- or double-direction thrust loads. These rollers have a length perpendicular to the shaft and have different shapes that affect the bearing's efficiency. The two rings on roller thrust bearings, called washers, are also configured with different shapes and designs. They can be flat, grooved, tapered, concave, convex, or grooved. There are several different types of roller thrust bearings. Cylindrical roller thrust bearings contain slightly crowned rollers that work well in one-direction thrust applications. Needle roller thrust bearings contain long, thin cylindrical rollers in a spoke-like configuration. Tapered roller thrust bearings contain conical rollers for single- or double-direction thrust loads. A tapered raceway matches each side of the rollers for smooth rolling motion. Spherical roller thrust bearings contain contoured rollers arranged in a steep, angular position. Spherical roller thrust bearings are self-aligning and capable of accommodating shaft misalignment.

Hot Searches

- • r - Fillet Chamfer TIMKEN 160TP165 Thrust cylindrical roller bearings PDF

- • Static Load Rating TIMKEN 220TP174 Thrust cylindrical roller bearings PDF

- • Dynamic Load Rating TIMKEN 220TP176 Thrust cylindrical roller bearings PDF

- • Chamfer r1smin4 TIMKEN A-5228-WS Cylindrical Roller Radial Bearing PDF

- • Speed Ratings - Grease TIMKEN HJ-8010432 Cylindrical Roller Radial Bearing PDF

- • Chamfer r1smin4 TIMKEN A-5220-WS Cylindrical Roller Radial Bearing PDF

- • Dynamic Load Rating C11 TIMKEN A-5238-WS Cylindrical Roller Radial Bearing PDF

- • Chamfer rsmin TIMKEN A-5232-WS Cylindrical Roller Radial Bearing PDF

- Four-Row Cylindrical Roller Radial Bearings

- Angle of Chamfer r1smin TIMKEN 500RX2345A Four-Row Cylindrical Roller Radial Bearings

- Outer-Ring Set TIMKEN 500RX2422 Four-Row Cylindrical Roller Radial Bearings

- DUR/DOR F/E TIMKEN 820RX3264A Four-Row Cylindrical Roller Radial Bearings

- Cylindrical Roller Radial Bearing

- Width B TIMKEN 390RY2103 Cylindrical Roller Radial Bearing

- Reference Thermal Speed Rating (Grease) TIMKEN NU5148MA Cylindrical Roller Radial Bearing

- Backing Shaft Diameter ds TIMKEN NNU4084MAW33 Cylindrical Roller Radial Bearing

- Single row Cylindrical roller bearing

- 150 mm x 320 mm x 65 mm Dynamic load, C NTN NU330C4 Single row Cylindrical roller bearing

- 110 mm x 240 mm x 50 mm da min NTN NU322ET2 Single row Cylindrical roller bearing

- 35 mm x 72 mm x 17 mm da max SNR NU.207.E.G15 Single row Cylindrical roller bearing

- About Us

- Company Profile

- Contact Info

- Site Map

- Sitemaps